×

Search

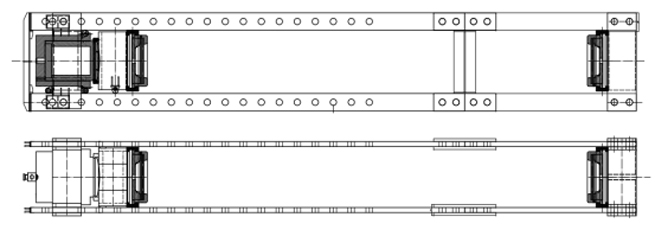

The hydrostatic pressure machine adopts the current international mature and reliable advanced technology and technology, the main goal is: to test the quality of finished products and eliminate stress. Product physical quality, production cost, various consumption indicators and labor productivity meet the requirements of product technology and efficiency. This pipe pressure testing machine is a pressure test of a single steel pipe, with a four-tension beam structure, and adopts the radial sealing form of the nozzle.

1.1 Purpose: Used for hydrostatic testing of steel pipes.

1.2 Type: Single station four beam type, with end face sealing.

1.3 Main components: tensile beam, mobile test head device, lifting roller, upper protection device, front and rear test heads, fixed test head device, low-pressure water system, pressurization system, hydraulic and electrical control equipment, etc.

| Hydraulic press capacity: | 1500 tons |

| Test steel pipe diameter: | Φ 426~ Φ 1422 mm |

| Length: | 5-12.5 m |

| Maximum test pressure: | 20 MPa |

| Holding time: | 5-10 seconds |

| Hydraulic system working pressure: | high-pressure system maximum 25 MPa |

| Low pressure system maximum 14 MPa | |

3.1 Stretch beam:

Four 400X120mm rectangular cross-section beams.

3.2 Mobile test head device:

Including mobile seat, main hydraulic cylinder, adjustable inspection head, and connection part between seat and stretching beam.

The mobile test head is equipped with a vent valve, which is opened and closed by the oil cylinder.

The moving test head and the tensile beam are connected with hydraulic pins.

3.3 Lifting roller

The lifting roller is driven by an oil cylinder and guided by four guide rods.

3.4 Fixed test head device

Including the support and the connection part with the stretching beam, low-pressure water sealing valve, etc.

The low-pressure water seal valve is installed on a fixed test head, and the upper part of the valve body is equipped with a high-pressure inlet hole.

3.5 Low pressure water system

It includes a centrifugal water pump and a set of Plumbing.

3.6 Boosting system

Including a plunger type high-pressure pump, a set of one-way valve groups, and a set of pressure transmitters.

When the pressure in the steel pipe rises to the required pressure, the pressure transmitter sends a signal to start maintaining pressure.

The pressurization system is connected to the tap water pipe to prevent impurities from entering the system and causing blockage.

3.7 Hydraulic System Description:

3.7.1 System Introduction:

The hydraulic system of the hydraulic press is equipped with one high-pressure hydraulic station and one low-pressure hydraulic station. The low-pressure hydraulic station controls all oil cylinders except for the main hydraulic cylinder, and the high-pressure hydraulic station controls the pressurization of the main hydraulic cylinder.

3.7.2 Operation:

When conducting the first pressure test, the oil pump motor should be started first, and the pressure should be adjusted from small to large according to the required pressure of each part. Then, each oil cylinder should be operated one by one to move without load. After the action is correct, the material can be loaded for operation. If insufficient pressure is found during the work process, the pressure can be slowly increased, but it cannot exceed the maximum system pressure. In the future, the oil pump motor should be started first when working, and the hydraulic system should be checked for normal operation before starting the pressure test.

3.7.3 Precautions:

When adjusting the pressure, it should be slowly adjusted from small to large, and the pressure should not be set too high at once.

3.7.4 Inspection of hydraulic oil:

3.7.4.1 The hydraulic oil in the oil tank should always maintain a normal oil level.

3.7.4.2 Hydraulic oil should be kept clean.

3.7.4.3 The oil needs to be regularly inspected and maintained. After one month of the first trial production, the oil should be replaced and cleaned once a month thereafter.

This equipment consists of pre water pressure preparation equipment, water pressure machine host, and post water pressure outlet pipe rack

The main pipe hydro testing machine of the hydraulic press is composed of movable supports, fixed supports, stretching beams (four pieces), custody car devices, sealing fixtures, high-pressure water system, low-pressure water system, hydraulic system, electrical system, etc.

Introduction to the Structure of Main Mechanical Equipment Components

1. Mobile support

The mobile support is a mobile type, consisting of a welded seat, a walking mechanism, a main hydraulic cylinder, an auxiliary hydraulic cylinder, a pressure testing head, an exhaust valve, a pin positioning device, a mobile end hydraulic station, etc.

2. Fixed support

The fixed support device is a fixed type, consisting of a fixed support, a low-pressure water sealing valve group, a high-pressure water unloading valve group, an exhaust valve, etc.

3. Stretch beam

The tensile beam is a solid tensile beam in the middle plate, consisting of four pieces. The two ends of the four tension beams are connected to the movable and fixed supports using cylindrical pins. The mobile support device can be moved within a rectangular frame and locked onto the position hole of the tension beam with a pin.

4. Lifting and hosting device

This device consists of two fixed and mobile custody devices, two sets of custody devices, one of which is connected to the mobile seat, and the steel pipe moves with the mobile seat when the length changes.

The pressure test station lifts the roller up → the sealing head of the moving seat moves forward → the exhaust gas is opened → the water inlet valve is opened → the low pressure water is filled → the water inlet valve is closed → the exhaust and discharge are closed → pressurization → pressure holding, display and record pressure value, print the pressure curve, save the pressure test record→exhaust and discharge open→the moving seat retreats and the pipe moves laterally→the lifting roller descends→the steel pipe is hoisted out by the crane→the next cycle

Large Diameter Spiral Welded Pipe Production Line

Small Diameter Spiral Welded Pipe Production Line

Heavy Duty Spiral Welded Pipe Production Line

Thin Wall Spiral Welded Pipe Production Line

Stainless Steel Spiral Welded Pipe Production Line

Hydrostatic Pressure Testing Machine for Large Diameter Pipe

Hydrostatic Pressure Testing Machine for Small Diameter Pipe

Hydrostatic Pressure Testing Machine for Ultra High Pressure Steel Pipe

Chamfering Machine for Large Diameter Steel Pipe End

Chamfering Machine for Small Diameter Steel Pipe End

Double Station Chamfering Machine for Steel Pipe

Automatic Steel Pipe Chamfering Machine

High Frenquency Welded Pipe Production Line for Large Diameter Pipe

High Frenquency Welded Pipe Production Line for Small Diameter Pipe

Steel Pipe Conveyor

Steel Pipe Rotating Roller Table

Steel Pipe Puller

Steel Pipe Dropper

Steel Pipe Storage Rack

3PE Anti-corrosion Steel Pipe Production Line

Plastic Coated Steel Pipe Anti-Corrosion Production Line

Polyethylene (PE) Insulated Steel Pipe Production Line

Quick Links

Address

Tel

+86-0317-6213222Quick Links

Address

South Industrial Development Zone, Yanshan County, Cangzhou City, Hebei Province

Phone

+86-0317-6213222

_20250326101307.webp)